فيما يلي وصف للخلاط JS3000XC من NFLG JS3000XC وقطع الغيار

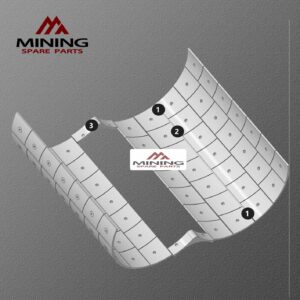

| لا. | المواصفات | الكمية | وزن الوحدة (كجم) | الوزن الإجمالي (كجم) | الملاحظات |

| 1 | الماس | 84 | 6 | 504 | |

| 2 | شبه منحرف | 28 | 5.9 | 165.2 | |

| 3 | بطانة صغيرة | 18 | 5.8 | 104.4 | |

| 4 | بطانة النهاية 1 القوس الكبير | 16 | 18.8 | 300.8 | |

| 5 | بطانة النهاية 2 قوس صغير | 24 | 7.2 | 172.8 | |

| 6 | بطانة النهاية 3 ل.ر.ع.م.1 | 4 | 15.8 | 63.2 59.2 | |

| 7 | بطانة النهاية 4 ل.ر منتظم 2 | 4 | 14.8 | 74.4 | 瓦头 |

| 8 | باب واحد

صفيحة السيلنج |

4 | 18.6 | 226.8 | |

| 9 | الشفرة الوسطى | 14 | 16.2 | 74.4 | |

| 10 | الشفرة اليسرى | 4 | 18.6 | ||

| 11 | الشفرة اليمنى | 2 | 17.2 | 34.4 | |

| 12 | السكين الأيسر | 4 | 9.4 | 37.6 | |

| 13 | السكين الأيمن | 2 | 9.2 | 18.4 | |

| 14 | الذراع الوسطى | 14 | 58.2 | 814.8 | |

| 15 | الذراع الأيسر | 4 | 63.2 | 252.8 | |

| 16 | الذراع الأيمن | 2 | 62.8 | 125.6 | |

| الإجمالي | 228 | 3028.8 |

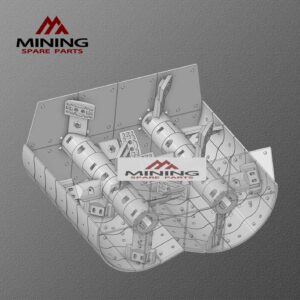

في عالم التميز في خلط الخرسانة، انظر إلى شفرات الخلاط ذات العمود المزدوج JS3000XC من NFLG، وأذرع الخلط، والبطانات. تضمن لك هذه البدائل الأصلية المتانة، مما يضمن لك أداءً لا مثيل له وطول العمر. سواءً كنت تبحث عن بدائل أصلية من الدرجة الأولى أو تستكشف سوق ما بعد البيع، فإن منتجاتنا تمثل شهادة على الجودة والموثوقية.

وباعتبارنا شركة تصنيع ملتزمة بالابتكار والتميز، فإننا نفخر بصناعة مكونات تتكامل بسلاسة مع أنظمة الخلط الخاصة بك. يجسِّد مصطلح "الاستبدال الأصلي" تفانينا في الهندسة الدقيقة، مما يضمن أن كل شفرة، وذراع خلط، وبطانة تتوافق تمامًا مع مواصفات الخلاط.

في مجال ما بعد البيع، تستمر عروضنا في التألق. تتكامل مكوناتنا المصممة بدقة لتلبية معايير الصناعة أو تتجاوزها، بسلاسة في مختلف إعدادات الخلط. لا تتوقع أقل من الأداء الأمثل وطول العمر، مما يتيح لك زيادة عمر الخلاط الخاص بك إلى أقصى حد.

المتانة هي حجر الزاوية في فلسفة التصميم لدينا. نحن نتفهم الطبيعة المتطلبة لتطبيقات خلط الخرسانة، ومنتجاتنا مصممة لتتحمل. يضمن البناء القوي للشفرات وأذرع الخلط والبطانات لدينا مقاومة التآكل والتلف، مما يجعلها أصولاً يمكن الاعتماد عليها في عمليات الخلط الخاصة بك.