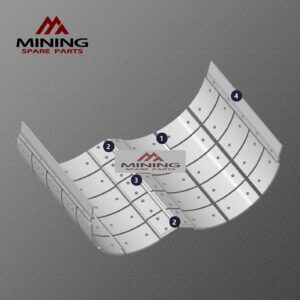

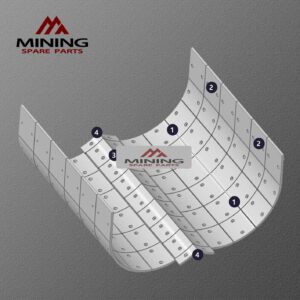

فيما يلي وصف لخلاط NFLG 3000G وأجزائه

| لا. | المواصفات | رمز السلعة | الكمية | وزن الوحدة (كجم) | الملاحظات |

| 1 | لوحة ختم باب التفريغ | JS2250XC-3-3-3 | 4 | 18.6 | |

| 2 | شريط ختم باب التفريغ | JS2250XC-3-2 JS2250XC-3-2 | 16 | 5.8 | |

| 3 | بطانة القوس العلوي | JS3000XD6-3-1 JS3000XD6-3-1 | 8 | 24 | |

| 4 | الماس | JS3000XD-3-11 | 98 | 6.4 | |

| 5 | شبه منحرف | JS3000XD-3-12 | 28 | 6.8 | |

| 6 | بطانة نهاية القوس الصغير | JS3000XD-3-7 | 24 | 7.3 | |

| 7 | بطانة نهاية القوس المنفصل | JSL2000XE-3-3-3 | 32 | 9.7 | |

| 8 | بطانة نهاية البطانة 1 | JS3000XD-3-4 | 2 | 15.8 | |

| 9 | بطانة نهاية البطانة 2 | JS3000XD-3-5 | 2 | 15.8 | |

| 10 | نهاية البطانة اليمنى للزاوية اليمنى lrregular 1 | JS2250XC-3-6 | 2 | 14.8 | |

| 11 | بطانة نهاية البطانة القائمة الزاوية اليمنى lrregular 2 | JS2250XC-3-8 | 2 | 14.8 | |

| 12 | شفرة الإرجاع الجانبي | JSL3000-5-1 JSL3000-5-1 | 2 | 24.2 | |

| 13 | شفرة الإرجاع العلوية | JSL2250XC-5-4 | 2 | 17 | |

| 14 | إرجاع الشفرة السفلية | JSL2250XC-5-5 JSL2250XC-5 | 2 | 9.2 | |

| 15 | شفرة التغذية العلوية | JSL2250XC-5-7 | 2 | 18.4 | |

| 16 | شفرة التغذية السفلية | JSL2250XC-5-8 | 2 | 9.4 | |

| 17 | شفرة التغذية A | JSL3000-5-2 JSL3000-5-2 | 6 | 26.2 | |

| 18 | شفرة التغذية 8 | JSL3000-5-9 | 8 | 22.8 | |

| 19 | شفرة تغذية جانبية | JSL3000-3000-5-6 | 2 | 26.8 | |

| 20 | ذراع خلط التغذية | JSL3000G-5-5 JSL3000G-5 | 14 | 53.6 | |

| 21 | تغذية المقعد السفلي | JSL3000G-5-1 JSL3000G-5-1 | 2 | 25 | |

| 22 | ذراع خلط التغذية الجانبية | JSL3000G-5-3 JSL3000G-5-3 | 2 | 57.85 | |

| 23 | ذراع الخلط المرتد الجانبي | JSL3000G-5-4 | 2 | 53.6 | |

| 24 | غلاف المشبك | JSL4000XC-5:4-3 | 4 | ||

| 25 | فاصل | JSL3000-5-14 | 4 | 17.4 | |

| 26 | غلاف العمود | JSL3000-5-11 | 20 |

في منشأة التصنيع الخاصة بنا، نفخر بصناعة شفرات الخلاط المزدوجة العمود المزدوج NFLG 3000G، وأذرع الخلط، والبطانات التي تجسد جوهر الاستبدال الأصلي. يمتد التزامنا بالتميز إلى ما هو أبعد من مجرد قطع الغيار؛ فهو يشمل الفهم الشامل لأهمية حلول ما بعد البيع والمتانة المطلوبة في مجال خلط الخرسانة المتطلب.

يشير الاستبدال الأصلي، في سياقنا، إلى الهندسة الدقيقة والتصنيع الدقيق الذي يدخل في كل مكون من مكونات NFLG 3000G. نحن نلتزم بأعلى معايير الصناعة، مما يضمن اندماج منتجاتنا بسلاسة في الماكينات الأصلية، مما يوفر ملاءمة مثالية وأداءً مثاليًا. ويضمن هذا الالتزام بالأصالة أن يواجه المشغلون أقل وقت تعطل، حيث إن مكوناتنا مصممة لتعكس مواصفات الماكينات الأصلية بدقة.

المتانة هي حجر الزاوية في فلسفتنا التصنيعية. نحن ندرك أنه في بيئة خلط الخرسانة القاسية، لا مفر من البلى والتلف. لذلك، تم تصميم مكونات NFLG 3000G لدينا لتتحمل قسوة الاستخدام الشاق. لا تضمن المواد المستخدمة والدقة في الصناعة الحرفية طول العمر فحسب، بل تضمن الأداء المستدام في ظل الظروف الصعبة.

في الختام، عندما تختار شفرات الخلاط ثنائي العمود NFLG 3000G وأذرع الخلط والبطانات الخاصة بنا، فإنك تختار قطع الغيار الأصلية التي تتكامل بسلاسة، وحلول ما بعد البيع التي تفوق التوقعات، والمتانة التي تصمد أمام اختبار الزمن. التزامنا لا يقتصر على تزويدك بمكونات فحسب، بل شركاء موثوق بهم في نجاح عمليات خلط الخرسانة الخاصة بك.