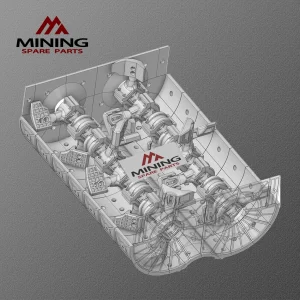

فيما يلي وصف لخلاط كالونغ CL-1200 وأجزائه

| الموديلات:CA-Long CL-1200 | |||||

| المنصب | رمز العنصر | الفئة | الكمية/المجموعة | الوزن الصافي | |

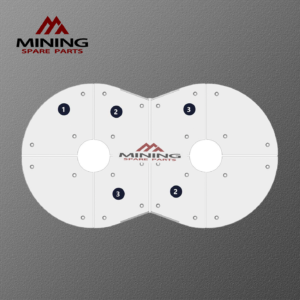

| الذراع والنصائح | 1 | CL1200.7.1.14 | ① طرف الخلط ① | 8 | 4.5 |

| 2 | CL1200.7.1.17 | ④ طرف الخلط ④ | 20 | 5.5 | |

| 3 | CL1200.7.1.15 | ② ذراع الخلط العكسي | 4 | 12 | |

| 4 | CL1200.7.1.16 | ③ ذراع الخلط الإيجابي | 24 | 12 | |

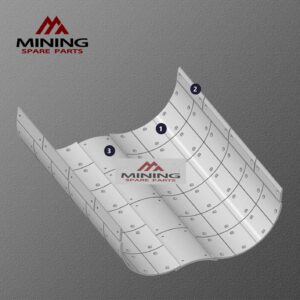

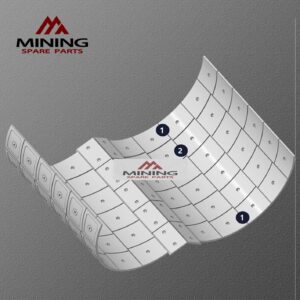

| البطانات | بطانات في الخلاط (بما في ذلك 60 قطعة) | ||||

| بطانة الحائط | 1 | CL1200.7.1.20 | بطانات ARC | 24 | 8 |

| 2 | CL1200.7.7.1.23 | بطانة جانبية | 8 | 5.5 | |

| 3 | CL1200.7.1.45 | البطانة السفلية | 2 | 9.8 | |

| 4 | CL1200.7.1.22 | بطانة البوابة | 10 | 10 | |

| بطانة النهاية | 6 | CL1200.7.7.1.19 | بطانة النهاية I | 8 | 11.5 |

| 7 | CL1200.7.1.21 | بطانة النهاية II | 4 | 10.5 | |

| 8 | CL1200.7.7.1.23 | بطانة النهاية III | 4 | 10.5 | |

| مرشح الغبار | أكياس الترشيح 223*58*1920 | 432 | |||

| لا يوجد | العناصر | المواصفات | الكمية | مستخدمة في | الملاحظات | توفر L/M | |

| 1 | أسطوانة مسطحة | ل=600 ± 89 | 10 | جهاز كمبيوتر شخصى | حزام ناقل التغذية الناقل | نعم | |

| أسطوانة مضادة للميل | ل=600 ± 60 | 4 | جهاز كمبيوتر شخصى | حزام ناقل التغذية الناقل | نعم | ||

| سلسلة الإرسال الترددي | 10A-2X20 | 4 | مجموعات | حزام ناقل التغذية الناقل | نعم | ||

| الحزام الناقل | العرض=500 مم، سمك 10 مم | 2 | جهاز كمبيوتر شخصى | حزام ناقل التغذية الناقل | 3220 | نعم | |

| المحمل الجالس | UCP209 | 16 | جهاز كمبيوتر شخصى | حزام ناقل التغذية الناقل | اليابان | نعم | |

| 2 | اضغط على العجلة | CL1200.2.2.3.3.3.4 | 2 | جهاز كمبيوتر شخصى | الحزام الناقل الأفقي | نعم | |

| عجلة مسننة طرف المحور | CL1200.2.9 | 1 | جهاز كمبيوتر شخصى | الحزام الناقل الأفقي | نعم | ||

| عجلة مسننة المحرك | CL1200.2.2.11 | 1 | جهاز كمبيوتر شخصى | الحزام الناقل الأفقي | نعم | ||

| سلسلة الإرسال | 12A-1X106 | 1 | مجموعة | الحزام الناقل الأفقي | نعم | ||

| المحمل الجالس | UCF210 | 4 | جهاز كمبيوتر شخصى | الحزام الناقل الأفقي | اليابان | نعم | |

| المحمل الجالس | UCP206 | 2 | جهاز كمبيوتر شخصى | الحزام الناقل الأفقي | اليابان | نعم | |

| بكرة جانبية | ل=290 ± 76 | 10 | جهاز كمبيوتر شخصى | الحزام الناقل الأفقي | نعم | ||

| الأسطوانة الوسطى | ل=190 °76 °190 | 10 | جهاز كمبيوتر شخصى | الحزام الناقل الأفقي | نعم | ||

| الحزام الناقل | العرض=500 مم، سمك 12 مم | 100 | m | الحزام الناقل الأفقي | نعم | ||

| 3 | السلسلة | 12A-1X88 | 1 | مجموعة | سير ناقل مائل ناقل مائل | نعم | |

| المحمل الجالس | UCF210 | 2 | جهاز كمبيوتر شخصى | سير ناقل مائل ناقل مائل | اليابان | نعم | |

| مقعد المحمل المتداول | SN210 | 2 | جهاز كمبيوتر شخصى | سير ناقل مائل ناقل مائل | اليابان | نعم | |

| المحمل المتداول | محمل كروي 1210 | 2 | جهاز كمبيوتر شخصى | سير ناقل مائل ناقل مائل | اليابان | نعم | |

| عجلة مسننة السائق (SEW) | CL1200.3.7 | 1 | جهاز كمبيوتر | سير ناقل مائل ناقل مائل | نعم | ||

| عجلة مسننة مدفوعة | CL1200.3.3.9.1 | 1 | جهاز كمبيوتر | سير ناقل مائل ناقل مائل | نعم | ||

| 4 | مقعد المحمل | SN218 | 2 | جهاز كمبيوتر شخصى | بكرة تجفيف الأسطوانة | مقعد المحمل المتداول | نعم |

| المحمل | 53518 | 2 | جهاز كمبيوتر شخصى | بكرة تجفيف الأسطوانة | محمل أسطواني قابل للتعديل على القلب | نعم | |

| المحمل | 7211E | 2 | جهاز كمبيوتر شخصى | بكرة تجفيف الأسطوانة | اليابان | نعم | |

| المحمل | 7212E | 2 | جهاز كمبيوتر شخصى | بكرة تجفيف الأسطوانة | اليابان | نعم | |

| السلسلة | 16A-2X16 | 4 | مجموعات | بكرة تجفيف الأسطوانة | نعم | ||

| ميزان حرارة معدني مزدوج | WSS-502 | 1 | جهاز كمبيوتر | بكرة تجفيف الأسطوانة | نعم | ||

| صفيحة صغيرة في الأسطوانة | CL1200.4.4.2.1 | 9 | جهاز كمبيوتر شخصى | بكرة تجفيف الأسطوانة | لا يوجد | ||

| صفيحة صغيرة في الأسطوانة | CL1200.4.4.2.2.2 | 12 | جهاز كمبيوتر شخصى | بكرة تجفيف الأسطوانة | لا يوجد | ||

| صفيحة صغيرة في الأسطوانة | CL1200.4.2.2.3 | 72 | جهاز كمبيوتر شخصى | بكرة تجفيف الأسطوانة | لا يوجد | ||

| صفيحة صغيرة في الأسطوانة | CL1200.4.2.2.7 | 8 | جهاز كمبيوتر شخصى | بكرة تجفيف الأسطوانة | لا يوجد | ||

| عجلة مسننة1 | CL1200.4.4.5.5.5 | 2 | جهاز كمبيوتر شخصى | بكرة تجفيف الأسطوانة | لا يوجد | ||

| عجلة مسننة2 | CL1200.4.4.5.6 | 2 | جهاز كمبيوتر شخصى | بكرة تجفيف الأسطوانة | لا يوجد | ||

| 5 | المحمل | UCFL205 | 2 | جهاز كمبيوتر شخصى | نظام الحرق والتدفئة | نعم | |

| المحمل المشترك | SGS-M8 | 2 | جهاز كمبيوتر شخصى | نظام الحرق والتدفئة | نعم | ||

| محرك مؤازر | DWR-100 | 1 | جهاز كمبيوتر | نظام الحرق والتدفئة | نعم | ||

| صمام الملف اللولبي | AB41-03-2 DN10 | 1 | جهاز كمبيوتر | نظام الحرق والتدفئة | نعم | ||

| صمام الملف اللولبي | AB41-03-2 DN15 | 1 | جهاز كمبيوتر | نظام الحرق والتدفئة | نعم | ||

| صمام الملف اللولبي | AB42-03-2 DN10 | 1 | جهاز كمبيوتر | نظام الحرق والتدفئة | نعم | ||

| كاشف اللهب | QRA2 | 1 | جهاز كمبيوتر | نظام الحرق والتدفئة | سيمنز | لا يوجد | |

| محول الإنجنيشن | 2 × 7 كيلو فولت | 1 | جهاز كمبيوتر | نظام الحرق والتدفئة | نعم | ||

| 6 | مقياس ضغط مقاوم للصدمات | YTGN-60 | 1 | جهاز كمبيوتر | نظام إمداد زيت الوقود | نعم | |

| مضخة التروس | ZYB-3/2.0 | 1 | جهاز كمبيوتر | نظام إمداد زيت الوقود | نعم | ||

| التصفية | ZU-A63×10S | 1 | جهاز كمبيوتر | نظام إمداد زيت الوقود | نعم | ||

| فوهة الموقد الرئيسي مع مدفع الزيت | CL1200 | 1 | جهاز كمبيوتر | نظام إمداد زيت الوقود | لا يوجد | ||

| 7 | سلسلة الإرسال | CL1200.6.6.8.1 | 1 | مجموعة | مصعد ساخن | سلسلة صفيحة المصعد الساخن | لا يوجد |

| سلسلة الإرسال | 24A-1X76 | 1 | مجموعة | مصعد ساخن | نعم | ||

| المحمل الجالس | UCT316 | 2 | جهاز كمبيوتر شخصى | مصعد ساخن | اليابان | نعم | |

| المحمل الجالس | UCP216 | 2 | جهاز كمبيوتر شخصى | مصعد ساخن | اليابان | – | |

| قادوس الركام | CL1200.6.6.5.2 | 50 | جهاز كمبيوتر شخصى | مصعد ساخن | نعم | ||

| عجلة مسننة مدفوعة | CL1200.6.6.3.11 | 1 | جهاز كمبيوتر | مصعد ساخن | نعم | ||

| رفع العجلة المسننة للسائق | CL1200.6.6.3.10 | 1 | جهاز كمبيوتر | مصعد ساخن | لا يوجد | ||

| عجلة مسننة السائق | CL1200.6.6.3.4 | 1 | جهاز كمبيوتر | مصعد ساخن | نعم | ||

| عجلة الرفع المدفوعة | CL1200.6.6.1.11 | 1 | جهاز كمبيوتر | مصعد ساخن | لا يوجد | ||

| 8 | قادوس الحشو | CL1200.7.6.6.3 | 10 | جهاز كمبيوتر شخصى | مصعد الحشو | نعم | |

| حزام الترباس | CL1200.7.7.6.2 | 50 | جهاز كمبيوتر شخصى | مصعد الحشو | نعم | ||

| الحزام الناقل | CL1200.7.6.6.1 | 1 | جهاز كمبيوتر | مصعد الحشو | – | ||

| بكرة السائق | CL1200.7.7.4.9 | 1 | جهاز كمبيوتر | مصعد الحشو | لا يوجد | ||

| عجلة مسننة سائق ناقل الحركة | CL1200.7.7.4.4.4 | 1 | جهاز كمبيوتر | مصعد الحشو | نعم | ||

| عجلة مسننة مدفوعة بناقل الحركة | CL1200.7.4.4.5 | 1 | جهاز كمبيوتر | مصعد الحشو | نعم | ||

| أسطوانة النقل | CL1200.7.7.1.9.7 | 1 | جهاز كمبيوتر | مصعد الحشو | لا يوجد | ||

| 9 | Screen1(1240x1280x24mm) | مقياس السلك Ф5.0 مم | 3 | جهاز كمبيوتر شخصى | شاشة اهتزازية | ارجع إلى الشكل 3 | نعم |

| Screen2(935x1280x18mm) | مقياس السلك Ф4.1 مم | 3 | جهاز كمبيوتر شخصى | شاشة اهتزازية | ارجع إلى الشكل 3 | نعم | |

| Screen3(1700x1280x10mm) | مقياس السلك Ф3.1 مم | 5 | جهاز كمبيوتر شخصى | شاشة اهتزازية | ارجع إلى الشكل 3 | نعم | |

| Screen4(1490x1280x5mm) | مقياس السلك Ф2.5 مم | 5 | جهاز كمبيوتر شخصى | شاشة اهتزازية | ارجع إلى الشكل 3 | نعم | |

| المحمل | 53617 | 2 | جهاز كمبيوتر شخصى | شاشة اهتزازية | اليابان | نعم | |

| حزام مثلث | B83 | 15 | جهاز كمبيوتر شخصى | شاشة اهتزازية | اليابان | نعم | |

| 10 | مؤشر المستوى | RP41B L=350 | 3 | جهاز كمبيوتر شخصى | صندوق ساخن | – | |

| اسطوانة | GPM100-120-FA5DW | 2 | جهاز كمبيوتر شخصى | صندوق ساخن | شركة JPC | نعم | |

| المحمل الجالس | UCF210 | 2 | جهاز كمبيوتر شخصى | صندوق ساخن | اليابان | نعم | |

| 11 | اسطوانة | gpm100-230-fa5dw | 1 | جهاز كمبيوتر شخصى | قادوس مقياس الركام | شركة JPC | |

| المحمل | UCF210 | 2 | جهاز كمبيوتر شخصى | قادوس مقياس الركام | اليابان | نعم | |

| مستشعر الضغط | 2 | جهاز كمبيوتر شخصى | قادوس مقياس الركام | توليدو | نعم | ||

| 12 | صمام فراشة هوائي | 1 | جهاز كمبيوتر | قادوس حشو الميزان الحشو | وام | لا يوجد | |

| مستشعر الضغط | SB-0.3 | 3 | جهاز كمبيوتر شخصى | قادوس حشو الميزان الحشو | توليدو | نعم | |

| 13 | اسطوانة | GPM63-163-120-FA5DW | 1 | جهاز كمبيوتر | قادوس القار القار | شركة JPC | نعم |

| مفتاح تبديل مستوى السائل الكروي العائم | UQKK-02 | 1 | جهاز كمبيوتر | قادوس القار القار | نعم | ||

| مستشعر الميزان | TSC-200 | 2 | جهاز كمبيوتر شخصى | قادوس القار القار | توليدو | نعم | |

| 14 | اسطوانة | gpm100-230-fa6dw | 1 | جهاز كمبيوتر | خلاط | شركة JPC | نعم |

| صمام الملف اللولبي | SR561A-RN35DW | 1 | جهاز كمبيوتر | خلاط | شركة JPC | نعم | |

| المحمل | 6005-2Z | 2 | جهاز كمبيوتر شخصى | خلاط | اليابان | نعم | |

| المحمل | 153520 | 1 | جهاز كمبيوتر شخصى | خلاط | اليابان | نعم | |

| مقعد المحمل | SN520 | 1 | جهاز كمبيوتر شخصى | خلاط | نعم | ||

| سلسلة الإرسال | 24A-2×18 | 2 | جهاز كمبيوتر شخصى | خلاط | سلسلة أسطوانية مزدوجة | نعم | |

| عجلة مسننة لموصل المحور Ⅱ | CL1200.15.31 | 2 | جهاز كمبيوتر شخصى | خلاط | نعم | ||

| عجلة مسننة لموصل المحور Ⅰ | CL1200.15.30.CL1200.15.30 | 2 | جهاز كمبيوتر شخصى | خلاط | نعم | ||

| العتاد | CL1200.15.15.28 | 2 | جهاز كمبيوتر شخصى | خلاط | لا يوجد | ||

| ① طرف الخلط ① | CL1200.15.7 | 8 | جهاز كمبيوتر شخصى | خلاط | ارجع إلى الشكل 2 | لا يوجد | |

| ④ طرف الخلط ④ | CL1200.15.10 | 20 | جهاز كمبيوتر شخصى | خلاط | ارجع إلى الشكل 2 | لا يوجد | |

| ② ذراع الخلط العكسي | CL1200.15.15.8 | 4 | جهاز كمبيوتر شخصى | خلاط | ارجع إلى الشكل 2 | لا يوجد | |

| ③ ذراع الخلط الإيجابي | CL1200.15.15.9 | 24 | جهاز كمبيوتر شخصى | خلاط | ارجع إلى الشكل 2 | لا يوجد | |

| ① بطانة جانبية | CL1200.7.1.18 | 8 | جهاز كمبيوتر شخصى | خلاط | ارجع إلى الشكل 1 | لا يوجد | |

| ② بطانة النهاية② بطانة النهايةⅠ | CL1200.7.7.1.19 | 8 | جهاز كمبيوتر شخصى | خلاط | ارجع إلى الشكل 1 | لا يوجد | |

| ③ بطانة القوس | CL1200.7.1.20 | 24 | جهاز كمبيوتر شخصى | خلاط | ارجع إلى الشكل 1 | لا يوجد | |

| ④بطانة النهاية ④ | CL1200.7.1.21 | 4 | جهاز كمبيوتر شخصى | خلاط | ارجع إلى الشكل 1 | لا يوجد | |

| ⑤بطانة البوابة | CL1200.7.1.22 | 10 | جهاز كمبيوتر شخصى | خلاط | ارجع إلى الشكل 1 | لا يوجد | |

| ⑥بطانة النهاية ⑥ | CL1200.7.7.1.23 | 4 | جهاز كمبيوتر شخصى | خلاط | ارجع إلى الشكل 1 | لا يوجد | |

| ⑦بطانة سفلية | CL1200.7.1.45 | 2 | جهاز كمبيوتر شخصى | خلاط | ارجع إلى الشكل 1 | لا يوجد | |

| 15 | اسطوانة | QGBZ125-400MP1-FB5DW | 1 | جهاز كمبيوتر | صومعة تخزين المزيج الساخن | شركة JPC | نعم |

| 16 | سلسلة الإرسال | 16A-2X18 | 1 | مجموعة | ناقل لولبي | سلسلة أسطوانية مزدوجة | نعم |

| حلقة مانعة للتسرب على شكل O | GB3452.1-82.GB3452.1-82 | 2 | جهاز كمبيوتر شخصى | ناقل لولبي | نعم | ||

| المحمل | UCF211 | 1 | جهاز كمبيوتر | ناقل لولبي | اليابان | نعم | |

| المحمل | GB292-83 | 2 | جهاز كمبيوتر شخصى | ناقل لولبي | نعم | ||

| عجلة مسننة طرف المحور | CL1200.25.25.3 | 1 | جهاز كمبيوتر | ناقل لولبي | نعم | ||

| عجلة مسننة المحرك | CL1200.25.25.2 | 1 | جهاز كمبيوتر | ناقل لولبي | نعم | ||

| 17 | مقياس المستوى | UL-GC250 | 1 | جهاز كمبيوتر | صومعة الحشو | نعم | |

| 18 | موصل الربط السريع | 10 | جهاز كمبيوتر شخصى | نظام هوائي | لا يوجد | ||

| مقياس الضغط | 1.6 ميجا باسكال | 2 | جهاز كمبيوتر شخصى | نظام هوائي | نعم | ||

| 19 | اسطوانة | GPM63-150MF1-FA5DW | 3 | جهاز كمبيوتر شخصى | نظام تنظيف الغبار | شركة JPC | نعم |

| اسطوانة | GPM80-100-FA5DK | 1 | جهاز كمبيوتر | نظام تنظيف الغبار | شركة JPC | نعم | |

| مروحة الطرد | 1 | جهاز كمبيوتر | نظام تنظيف الغبار | لا يوجد | |||

| المحمل الجالس | UCP208 | 2 | جهاز كمبيوتر شخصى | نظام تنظيف الغبار | اليابان | نعم | |

| المحمل الجالس | UCF212 | 2 | جهاز كمبيوتر شخصى | نظام تنظيف الغبار | اليابان | نعم | |

| السلسلة | 20A-1×68 | 1 | مجموعة | نظام تنظيف الغبار | GB1243.1-83 | نعم | |

| مانع تسرب مطاطي للبوابة | 18 | جهاز كمبيوتر شخصى | نظام تنظيف الغبار | لا يوجد | |||

| كيس الترشيح | 223×58×19209(Ellipse) | 100 | جهاز كمبيوتر شخصى | نظام تنظيف الغبار | الولايات المتحدة الأمريكية دو بونت | لا يوجد | |

| 20 | ميزان حرارة معدني مزدوج | WSS501 0-300 | 2 | جهاز كمبيوتر شخصى | نظام تسخين وتخزين البيتومين | L=100 | نعم |

| WSS501 0-300 | 2 | جهاز كمبيوتر شخصى | نظام تسخين وتخزين البيتومين | L=800 | نعم | ||

| مقياس الضغط | YTZ-150 1.6 ميجا باسكال | 2 | جهاز كمبيوتر شخصى | نظام تسخين وتخزين البيتومين | نعم | ||

| مقياس مستوى الزيت | 0-200℃ L=700 | 1 | جهاز كمبيوتر | نظام تسخين وتخزين البيتومين | نعم | ||

| اسطوانة | QGBZ100-150MP3-FA5TK | 1 | جهاز كمبيوتر | نظام تسخين وتخزين البيتومين | شركة JPC | نعم | |

| 21 | أطقم إصلاح أسطوانات الهواء | GPM100 -120-FA5DW | 2 | مجموعات | هوت بن | ||

| أطقم إصلاح أسطوانات الهواء | qgbz125 - 400-mp1-fb5dw | 2 | مجموعات | حاوية المخزون | |||

| أطقم إصلاح أسطوانات الهواء | GPM100 - 230-FA5DW | 2 | مجموعات | المقياس الإجمالي | |||

| أطقم إصلاح أسطوانات الهواء | gpm100-230-fa6dw | 2 | مجموعات | خلاط | |||

| أطقم إصلاح أسطوانات الهواء | GPM63-150-MF1-FA5DW | 5 | مجموعات | بيت الحقيبة | |||

| أطقم إصلاح أسطوانات الهواء | GPM63 -120-MF1-FA5DW | 1 | مجموعة | مقياس البيتومين | |||

| أطقم إصلاح أسطوانات الهواء | GPM80-100-FA5DK | 1 | مجموعة | صمام أمان منزل الحقيبة | |||

بصفتنا شركة رائدة في تصنيع شفرات خلاط كالونغ CL-1200 ثنائية العمود وأذرع الخلط والبطانات، فإن التزامنا بالتميز واضح في مكوناتنا الأصلية البديلة. وتقف هذه الأجزاء شاهدًا على الهندسة الدقيقة، مما يضمن التكامل السلس والأداء الأمثل.

إن دعمنا لما بعد البيع يتجاوز مجرد الاستبدال؛ إنه تعهد بتعزيز كفاءة الخلاط وطول عمره. تتميز منتجاتنا بالمواد المتينة وتقنيات التصنيع المتقدمة مما يضمن تحملها لقسوة تطبيقات الخلط الصعبة.

يدل الاستبدال الأصلي على أكثر من مجرد التوافق - فهو يجسد تفانينا في توفير مكونات تعكس أو تتفوق على أداء المعدات الأصلية. تضمن الدقة في التصميم والبناء ملاءمة مثالية وتشغيلًا سلسًا وجودة ثابتة طوال دورة حياة الخلاط.

في مجال خدمات ما بعد البيع، نعطي الأولوية للابتكار، ونعمل باستمرار على تحسين منتجاتنا لتلبية معايير الصناعة المتطورة. ويمتد التزامنا إلى ما هو أبعد من توريد قطع الغيار؛ فنحن نسعى جاهدين لتحسين الأداء العام للخلاط وكفاءته وموثوقيته.

المتانة هي حجر الزاوية في فلسفة التصنيع لدينا. نحن ندرك أن الخلاطات ثنائية العمود تعمل في بيئات صعبة، وتتعرض لقوى شديدة ومواد كاشطة. ولذلك، تخضع الشفرات وأذرع الخلط والبطانات لدينا لاختبارات صارمة لضمان متانة استثنائية، مما يقلل من وقت التوقف عن العمل وتكاليف الصيانة.

وفي الختام، تجسد مكونات خلاط كالونج CL-1200 ثنائي العمود من كالونج جوهر الاستبدال الأصلي، والابتكار في ما بعد البيع، والمتانة التي لا مثيل لها. اختر منتجاتنا للحصول على مزيج سلس من الدقة والأداء وطول العمر في عمليات الخلط الخاصة بك.