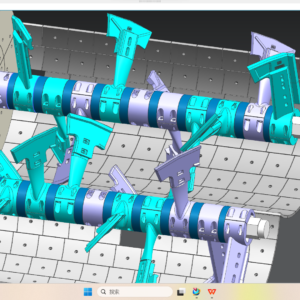

فيما يلي وصف للخلاط CO-NELE JS4500 وقطع الغيار

الخلاط ذو العمود المزدوج الأفقي المزدوج من سلسلة CS هو جيل جديد من الخلاطات التي طورتها شركة CO-NELE، والتي كانت أول من أدخل التكنولوجيا الألمانية المتقدمة في الصين وتعاونت مع الشركات الألمانية. وهي مقسمة إلى خلاط العمود الأفقي المزدوج عالي الكفاءة من سلسلة CHS، وخلاط الحزام الحلزوني المزدوج من سلسلة CDS، وخلاط الماء CWS. تُستخدم على نطاق واسع في إنتاج الخرسانة التجارية، والخرسانة الهيدروليكية، والمكونات الجاهزة، والمواد البيئية، ومواد الجدران، وغيرها من المواد.

ميزات الخلاط ذو العمود الأفقي المزدوج عالي الكفاءة CHS:

تم تجهيز مانع تسرب طرف العمود بحلقة مانع تسرب زيت عائم ومكون مانع تسرب مصمم خصيصًا، مما يشكل هيكل مانع تسرب متعدد الطبقات. يتميز مانع التسرب بالموثوقية والثبات العالي والعمر الافتراضي الطويل.

مجهز بنظام تشحيم أوتوماتيكي بالكامل، مع أربع مضخات زيت تعمل بشكل مستقل توفر إمدادات زيت عالية الضغط. يشتمل تصميم تركيب المحرك المثبت في الجزء العلوي على جهاز الشد الذاتي للسير الحاصل على براءة اختراع، مما يحسن كفاءة النقل، ويتجنب التآكل والتلف المفرط للسير، ويقلل من تكاليف الصيانة.

تتبنى الأسطوانة مفهوم تصميم نسبة الحجم الكبيرة، مما يعزز كفاءة الخلط بشكل فعال، ويطيل عمر مانع تسرب نهاية العمود، ويقلل من احتمالية التصاق المواد بالعمود.

صُمم باب التفريغ بفتحة كبيرة لمنع انسداد المواد وتسربها، مع تآكل منخفض، وإحكام إغلاق فعال، وتأثيرات طويلة الأمد. يعتمد جهاز الخلط على تصميم حاصل على براءة اختراع مع ترتيب بزاوية 60 درجة، مما يضمن خلطًا موحدًا ومقاومة منخفضة واحتمالية منخفضة لتشبث المواد بالعمود.

مزودة بعلبة تروس كوكبية من الدرجة العسكرية لنقل سلس وقدرة تحميل عالية. تشتمل الملحقات الاختيارية على علب تروس أصلية إيطالية، ومضخات تشحيم أوتوماتيكية ألمانية أصلية، وأجهزة تنظيف عالية الضغط، وأنظمة اختبار درجة الحرارة والرطوبة.

| الطراز | CHS750 | CHS1000 | CHS1250 | CHS1500 | CHS2000 | CHS2500 | CHS3000 | CHS3500 | CHS4000 | CHS4500 | CHS5000 | CHS6000 |

| سعة التغذية (لتر) | 1125 | 1500 | 1875 | 2250 | 3000 | 3750 | 4500 | 5250 | 6000 | 6750 | 7500 | 9000 |

| سعة التفريغ (لتر) | 750 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 |

| قوة محرك الخلط (KW) | 30 | 37 | 22×2 | 30×2 | 37×2 | 45×2 | 55×2 | 55×2 | 75×2 | 75×2 | 90×2 | 110×2 |

| طاقة محرك محطة الضخ (KW) | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| ذراع الخلط (قطعة) | 2*4 | 2*5 | 2*5 | 2*6 | 2*6 | 2*7 | 2*8 | 2*9 | 2*9 | 2*10 | 2*11 | 2*12 |

| لا. | المواصفات | الوحدة. | الكمية | وزن الوحدة (كجم) | الوزن الإجمالي (كجم) | الملاحظات |

| 1 | شفرة الخلط | أجهزة الكمبيوتر | 20 | 14.50 | 290.00 | |

| 2 | شفرة التغذية | أجهزة الكمبيوتر | 2 | 21.00 | 42.00 | |

| 3 | شفرة الإرجاع | أجهزة الكمبيوتر | 2 | 21.00 | 42.00 | |

| 4 | شفرة النهاية | أجهزة الكمبيوتر | 4 | 13.50 | 54.00 | |

| 5 | بطانة القوس I | أجهزة الكمبيوتر | 112 | 10.20 | 1142.40 | 菱 ↓ |

| 6 | بطانة القوس II | أجهزة الكمبيوتر | 32 | 10.50 | 336.00 | 梯 ↓↓ |

| 7 | بطانة النهاية 1 | أجهزة الكمبيوتر | 24 | 19.20 | 460.80 | |

| 8 | بطانة النهاية 2 | أجهزة الكمبيوتر | 16 | 13.60 | 217.60 | |

| 9 | بطانة النهاية 3 | أجهزة الكمبيوتر | 4 | 15.90 | 63.60 | |

| 10 | بطانة النهاية 4 | أجهزة الكمبيوتر | 4 | 15.90 | 63.60 | |

| 11 | ذراع الخلط | أجهزة الكمبيوتر | 20 | 66.50 | 1330.00 | |

| 12 | ذراع التغذية | أجهزة الكمبيوتر | 2 | 50.40 | 100.80 | |

| 13 | ذراع الإرجاع | أجهزة الكمبيوتر | 2 | 50.40 | 100.80 | |

| 14 | مقعد التوصيل | أجهزة الكمبيوتر | 24 | 24.00 | 576.00 | |

| 15 | فاصل | أجهزة الكمبيوتر | 22 | 16.40 | 360.80 | |

| الإجمالي | 244 | 5180.40 |

بصفتنا شركة رائدة في تصنيع شفرات الخلاط CO-NELE JS4500 ثنائية العمود وأذرع الخلط والبطانات، فإننا نؤكد على أهمية قطع الغيار الأصلية، التي تتميز بجودتها الفائقة وهندستها الدقيقة.

تلعب المكونات الأصلية البديلة دورًا محوريًا في الحفاظ على الأداء الأمثل للخلاط. عندما تختار CO-NELE JS4500، فإنك تختار الأصالة والموثوقية. إن التزامنا بإنتاج بدائل أصلية يضمن لك ملاءمة سلسة ومتناسقة مع الخلاط ويحافظ على كفاءة الخلاط وطول عمره.

وعلى النقيض من بدائل ما بعد البيع، تضمن بدائلنا الأصلية التوافق، مما يقلل من مخاطر الأعطال ووقت التعطل. نحن نعطي الأولوية للمواصفات الدقيقة والمواد عالية الجودة لتقديم مكونات تعكس أداء القطع الأصلية.