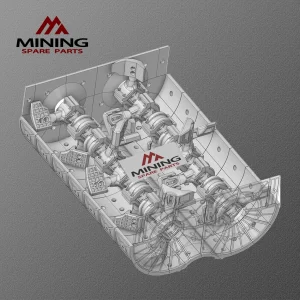

فيما يلي وصف للخلاط JS3000XD6.0 من NFLG JS3000XD6.0 وقطع الغيار

| لا. | المواصفات | رمز السلعة | الكمية | وزن الوحدة (كجم) | الوزن الإجمالي (كجم) | الملاحظات |

| 1 | دياماند | JS3000XD.3-11 | 98 | 6.4 | 627.2 | |

| 2 | شبه منحرف | JS3000XD.3-12 | 28 | 6.8 | 190.4 | |

| 4 | بطانة القوس العلوي | JS3000XD-6.3-1 JS3000XD-6.3-1 | 8 | 0 | 钢板 | |

| 5 | بطانة النهاية 1 | JS3000XD.3-7 | 24 | 7 | 168 | |

| 7 | بطانة النهاية 2 | JS3000XD.3-4 | 16 | 18.8 | 300.8 | |

| 8 | بطانة النهاية 3 | JS3000XD.3-5 | 4 | 15.8 | 63.2 | |

| 9 | بطانة النهاية 4 | JS3000XD.3-6 | 4 | 15.8 | 63.2 | |

| 10 | شريط ختم باب التفريغ | JS3000XD-6.3-2 JS3000XD-6.3-2 | 8 | 14.6 | 116.8 | |

| 11 | لوحة ختم باب التفريغ | JS3000XD-6.3-3 JS3000XD-6.3-3 | 2 | 31.2 | 62.4 | 瓦头 |

| 12 | شفرة تغذية جانبية | JSL3000.5-6 | 4 | 26.8 | 107.2. | |

| 13 | شفرة الإرجاع الجانبي A | JSL3000.5000.5-2 | 2 | 26.2 | 52.4 | |

| 14 | شفرة الإرجاع الجانبي B | JSL3000.5000.5-1 | 2 | 24.2 | 48.4 | |

| 15 | شفرة تغذية جانبية | JSL3000.5000.5-9 | 12 | 22.8 | 273.6 | |

| 16 | شفرة الإرجاع الجانبي | JSL3000.5000.5-3 | 4 | 23 | 92 | |

| 17 | ذراع خلط التغذية | JSL3000G.5-5 JSL3000G.5-5 | 10 | 53.6 | 536 | |

| 18 | ذراع الخلط المرتجع | JSL3000G.5-12 | 6 | 57.8 | 346.8 | |

| 19 | غلاف العمود | JSL3000.5000.5-11 | 24 | 20.95 | 502.8 | |

| 20 | فاصل | JS3000.5-14 | 8 | 11.4 | 91.2 | |

| الإجمالي | 264 | 3642.4 |

بصفتنا شركة رائدة في مجال التصنيع، نقدم بفخر مكونات الخلاط المزدوج العمود المزدوج NFLG JS3000XD6.0. يشير مصطلح "الاستبدال الأصلي" إلى التزامنا بالتركيب الدقيق، والحفاظ على الأداء والكفاءة المثلى. مع شفراتنا المصممة بدقة وأذرع الخلط والبطانات المصممة بدقة، فإن الخلاط الخاص بك يتلقى مكونات أصلية مصممة لتحقيق التكامل السلس وأقصى قدر من الإنتاجية.

في مجال حلول ما بعد البيع، تبرز عروضنا في عالم ما بعد البيع. فنحن نوفر بدائل لا تفي بمعايير الصناعة فحسب، بل تتجاوزها في كثير من الأحيان، ونقدم حلولاً فعالة من حيث التكلفة دون المساس بالجودة. تخضع مكونات ما بعد البيع لدينا لاختبارات صارمة، مما يضمن توافقها مع المعايير العالية التي تضعها المعدات الأصلية.

تصنيع دقيق ومواد عالية الجودة تميز مكوناتنا الأصلية البديلة. كل شفرة، وذراع خلط، وبطانة مصنوعة وفقًا لمواصفات دقيقة، مما يضمن ملاءمة سلسة وأداءً موثوقًا به. هذا التفاني في الدقة يقلل من وقت التوقف عن العمل وتكاليف الصيانة، مما يساهم في الكفاءة الكلية لعملياتك.

في مجال حلول ما بعد البيع، نحافظ على المستوى نفسه من ضمان الجودة. فمكونات ما بعد البيع لدينا مصممة بدقة متناهية وتلتزم بإجراءات صارمة لمراقبة الجودة. وهذا يضمن أنه حتى خياراتنا البديلة توفر الموثوقية وطول العمر، مما يلبي متطلبات مشاريع البناء المتنوعة.

إن متانة مكوناتنا دليل على التزامنا بالتميز. نحن نتفهم الظروف القاسية التي تعمل فيها معدات البناء، وقد صُممت شفراتنا وأذرع الخلط والبطانات لدينا لتتحمل هذه التحديات. الاستثمار في مكوناتنا المتينة يعني الاستثمار في طول عمر معداتك وكفاءتها.