فيما يلي وصف لخلاط SICOMA 3 المربع وأجزائه

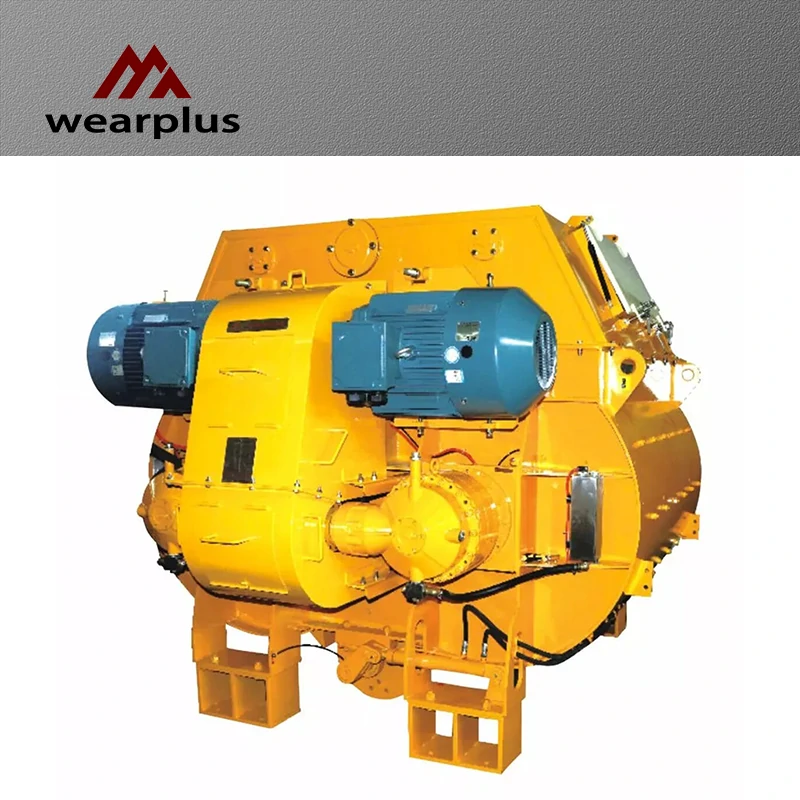

خلاطة الخرسانة سيكوما

تنتج شركة SICOMA مجموعة من الخلاطات متعددة الطرازات وفقًا لاحتياجات العملاء، تختار شركتنا معظم الإطارات الرئيسية MAOIMSO/MEO/MPC/AMP الرئيسية. تتكون الماكينة بشكل أساسي من سبعة أجزاء نظام: خزان الخلط / نظام الخلط / صندوق Juncfion / نظام المراقبة والإنذار / نظام التشحيم والسداد (ليس لسلسلة MPC/AMP) / نظام التفريغ / نظام النقل

خلاطة الخرسانة الإجبارية ثنائية العمود من سلسلة MAO القياسية MAO3000/2000 MAO4500/3000 MAO2250/1500

اتصل بنا

v الخدمة عبر الإنترنت

نهايات الشط حماية متعددة من التسرب وحماية من تسرب الهواء لمنع التسرب

نظام مراقبة الخلاط Uniquo لمراقبة تكاثف العمل في

مضخة باب التفريغ ومضخة باب التفريغ ومضخة التشحيم الإلكترونية

مع نظام مضخة الشحوم DC 24V نظام مضخة الشحوم DC 24V بيع خلاطة الخرسانة الخاصة tor

وقت تشغيل مبرمج.مقاوم للأتربة والغبار. أداء رائع

نظام سبرافينج المياه متعدد الأنابيب لضمان توزيع مياه الفرن.

عملية ديسيان ستابلو للخدمة الشاقة.

علبة التروس المعززة المعالجة بمواد عسكرية عالية الدقة

قدرة تحميل عالية وخدمة أطول.

تتراوح السعة من 15 متر مكعب إلى 6.0 متر مكعب.

نظام تلطيخ اختياري. نظام خالي من الشحوم والتبريد المائي ونظام ختم نهاية الشط نظام غسيل بالضغط العالي نظام غسيل بالضغط العالي نظام وزن نظام مراقبة الرطوبة

| الطراز | MAO3000/2000/2000 | MAO4500/3000 | MAO6000/4000 |

| سعة التعبئة الجافة (لتر) | 3000 | 4500 | 6000 |

| العائد المضغوط (L) | 2000 | 3000 | 4000 |

| سرعة الخلط (ص/م) | 24.5 | 24.5 | 24.5 |

| دورة (دورات) الخلط | 30 | 30 | 30 |

| شفرات الخلط (بريس) | 14 | 16 | 20 |

| محرك الخلط والقدرة (كيلوواط) | 2×37 | 2×55 | 2×75 |

| الوزن عند التفريغ (كجم) | 7500 | 9200 | 11800 |

النظام

| لا. | المواصفات | الكمية | الوحدة. | وزن الوحدة (كجم) | الوزن الإجمالي (كجم) | الملاحظات |

| 1 | الماس | 144 | أجهزة الكمبيوتر | 4.7 | 676.8 | زائد 5.5 ± 5.5 |

| 2 | شبه منحرف | 32 | أجهزة الكمبيوتر | 4.7 | 150.4 | زائد 5.5 ± 5.5 |

| 3 | المربع | 44 | أجهزة الكمبيوتر | 4.7 | 206.8 | زائد 5.4 :5.4 |

| 4 | ورقة المركز

6 |

16 | أجهزة الكمبيوتر | 16.6 | 265.6 | |

| 5 | ورقة جانبية | 4 | أجهزة الكمبيوتر | 16.5 | 66 | |

| 6 | مكشطة | 4 | أجهزة الكمبيوتر | 6 | 24 | |

| 7 | الذراع المركزي | 16 | أجهزة الكمبيوتر | 58.4 | 934.4 | |

| 8 | ذراع جانبية | 4 | أجهزة الكمبيوتر | 52 | 208 | |

| 9 | البطانة 1/2/1 | 16 | أجهزة الكمبيوتر | 12.8 | 204.8 | 13.2 |

| بطانة 3/4 | 8 | أجهزة الكمبيوتر | 14.1 | 112.8 | 14.6 | |

| البطانة 5/6 | 8 | أجهزة الكمبيوتر | 9.3 | 74.4 | 10.2 | |

| البطانة 7/8 | 16 | أجهزة الكمبيوتر | 8.3 | 132.8 | 8.6 | |

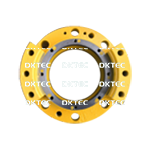

| 10 | 130 مباعد رينجل | 18 | أجهزة الكمبيوتر | 11.6 | 208.8 | |

| الإجمالي | 330 | 3265.6 |

تمثل شفرات خلاط SICOMA 3 المربعة ذات العمود المزدوج وأذرع الخلط والبطانات مثالاً للتميز في الاستبدال الأصلي. تتميز حلول ما بعد البيع لدينا، المصنوعة بدقة، بالمتانة التي تتفوق على المنافسين. يضمن التزامنا بالجودة تجربة استبدال سلسة. في مجال الخلاطات ذات العمود المزدوج، تمثل مكوناتنا شهادة على المرونة، حيث تقدم بديلاً متيناً يتجاوز معايير الصناعة. عندما يتعلق الأمر بالاستبدال الأصلي، فإننا نفخر بتقديم مكونات مصممة بدقة تتكامل بسلاسة مع الخلاط الخاص بك، مما يعيد إليه الأداء الأمثل.

في مجال خدمات ما بعد البيع، تتجاوز منتجاتنا مجرد البدائل؛ فهي ترقيات ترفع من كفاءة معداتك وطول عمرها الافتراضي. صُنعت حلولنا المتينة مع الاهتمام الدقيق بالتفاصيل، مما يضمن أنها لا تلبي المتطلبات القوية لبيئة الخلط فحسب، بل تتجاوزها. من خلال التركيز على مقاومة التآكل، تتحمل مكوناتنا قسوة التشغيل المستمر، مما يوفر طول العمر الذي يُترجم إلى توفير في التكاليف وتقليل وقت التعطل إلى الحد الأدنى.

يدل الاستبدال الأصلي على أكثر من مجرد التوافق؛ فهو يجسد الالتزام بالحفاظ على سلامة وكفاءة معداتك. تعمل عروض ما بعد البيع التي نقدمها على توسيع نطاق هذا الالتزام، مما يوفر حلاً موثوقًا ودائمًا يعزز الأداء العام للخلاط ثنائي العمود.