1- نظام التغذية الباردة

2- نظام توريد الأسمنت الأسفلتي

3- المجفف الكلي

5- نظام التحكم في الانبعاثات

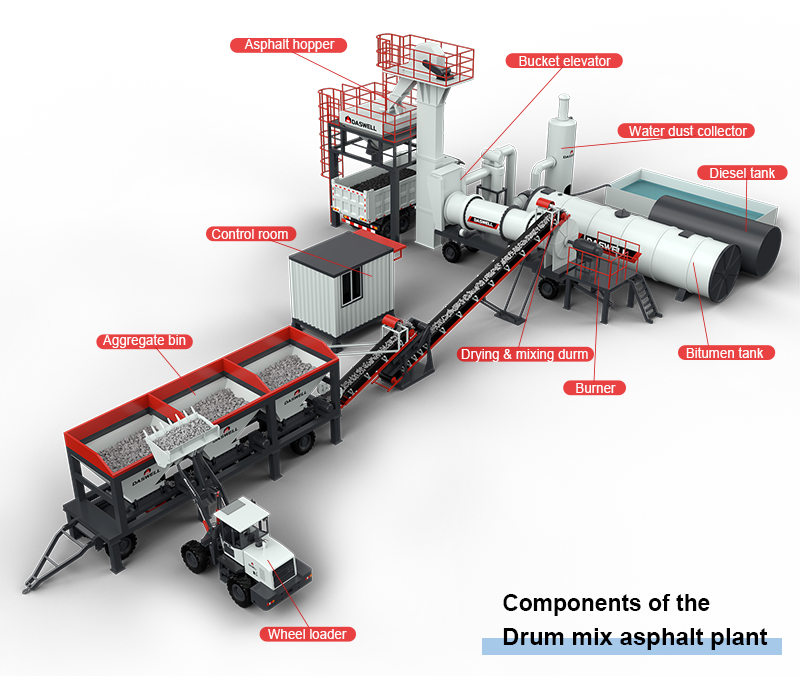

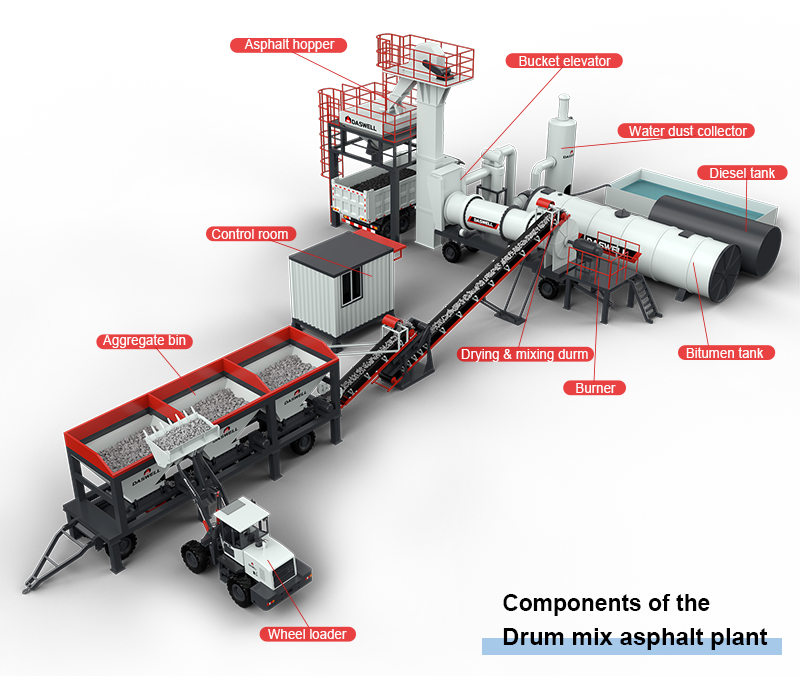

تعتبر مصانع خلط الأسفلت ضرورية لإنشاء الطرق والطرق السريعة والبنية التحتية. يعمل فهم تركيبها على تحسين الكفاءة والأداء في إنتاج الأسفلت.

1- نظام التغذية الباردة: نظام التغذية على البارد، وهو نظام محوري في إنتاج الأسفلت، يخزن بدقة ويحدد نسب الركام مثل الرمل والحصى والحجر.

2- نظام توريد الأسمنت الأسفلتي: مسؤول عن تخزين مادة الأسفلت الرابطة الأسفلتية وتسخينها، ويشمل هذا النظام الخزانات ومعدات التسخين وأجهزة القياس. استكشف الأفكار في https://miningspareparts.com/ لتعزيز أنظمة توريد الأسمنت الأسفلتي.

3- مجفف الركام: يضمن مجفف الركام الضروري لإزالة الرطوبة من الركام الخلط الأمثل وجودة الأسفلت.

4.برج الخلط (الخلط): في قلب مصنع خلط الأسفلت، يجمع برج الخلط بين الركام والمواد الرابطة الأسفلتية لإنتاج خلائط أسفلتية متنوعة. استكشف الوظائف على موقع miningspareparts.com لتحسين أبراج الخلط.

5- نظام التحكم في الانبعاثات: تُعد أنظمة التحكم في الانبعاثات جزءًا لا يتجزأ من الحد من تلوث الهواء، حيث تقوم أنظمة التحكم في الانبعاثات بالتقاط ومعالجة الانبعاثات الضارة. افهم أهميتها للاستدامة على موقع miningspareparts.com

الخلاصة: تعتبر مكونات مصنع خلط الأسفلت ضرورية لإنتاج خلائط أسفلتية عالية الجودة. ومن خلال فهم وظائفها، يمكن لأصحاب المصلحة تحسين الأداء من أجل تطوير البنية التحتية المستدامة.