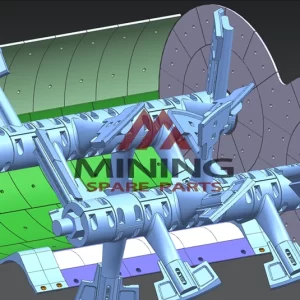

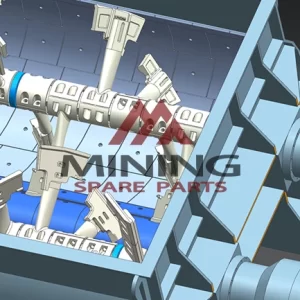

Here is a description of the FANGYUAN FJS2000 Mixer And Parts

| NO. | Specification | 图号 | Qty | Unit weight (Kg) | Total weight (Kg) | Remarks |

| 1 | Mixing Arm | FJS2000.3-18 | 10 | 54 | 540.00 | |

| 2 | Mixing Arm Seat | FJS2000.3-17 | 10 | 22 | 220.00 | |

| 3 | Side Mixing Arm | FJS2000.3-13 | 2 | 48.5 | 97.00 | |

| 4 | Reverse

Side Mixing Arm |

FJS2000.3-20 | 4 | 48.5 | 194.00 | |

| 5 | Side Mixing ArmSeat | FJS2000.3-14 | 6 | 21 | 126.00 | |

| 6 | Spacer Ring | FJS2000.3-22 | 14 | 15 | 210.00 | |

| 7 | Mixing Blade | FJS2000.2-19 | 10 | 17 | 170.00 | |

| 8 | Side Mixing Blade | FJS2000.2-15 | 2 | 16.8 | 33.60 | |

| 9 | Reverse side Mixing Blade | FJS2000.2-21 | 4 | 16.8 | 67.20 | |

| 10 | SideScraping Mixing Blade | FJS2000.2-16 | 6 | 14 | 84.00 | |

| 11 | Arc Lining Plate | FJS2000.1-1 | 144 | 4.5 | 648.00 | |

| 12 | Side Plate 1 | FJS2000.1-2 | 8 | 22.5 | 180.00 | |

| 13 | Side Plate 2 | FJS2000.1-3 | 16 | 19.5 | 312.00 | |

| 14 | Side Plate 3 | FJS2000.1-4 | 2 | 19.5 | 39.00 | 16Mn |

| 15 | Side Plate 4 | FJS2000.1-5 | 2 | 20 | 40.00 | 16Mn |

| 16 | Side Plate 5 | FJS2000.1-6 | 2 | 20 | 40.00 | 16Mn |

| 17 | Side Plate 6 | FJS2000.1-7 | 2 | 9.8 | 19.60 | 16Mn |

| 18 | Triangle Lining Plate | FJS2000.1-9 | 2 | 9 | 18.00 | |

| Total Quantity | 246 | 3038.4 |

Elevating the standard of excellence in the realm of concrete mixing, our FANGYUAN FJS2000 twin-shaft mixer blades, mixing arms, and liners are meticulously designed to embody the essence of original replacement, aftermarket versatility, and enduring durability.

When it comes to the aftermarket, our FJS2000 components go beyond mere replacements. They are engineered to elevate your mixer’s capabilities, providing enhanced features and functionalities. The aftermarket experience with our products is not just about restoration but about upgrading and optimizing your mixer’s performance to meet evolving industry demands.

Durability is the cornerstone of our design philosophy. Crafted with the finest materials and cutting-edge manufacturing techniques, our mixer blades, mixing arms, and liners exhibit unparalleled strength and wear resistance. This durability translates to a longer lifespan for your equipment, reducing downtime and maintenance costs.

As a leading manufacturer, we take pride in offering a comprehensive solution that caters to the diverse needs of the concrete mixing industry. Our commitment to smooth, reliable grammar is mirrored in the seamless functioning of our components, ensuring that every aspect of your mixing process is characterized by precision and efficiency.