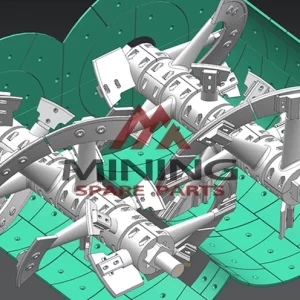

Here is a description of the SANY JS3000 JS3500 forced twin-shaft Mixer And Parts

| NO. | Specification | Item code | Unit. | Qty | Unit weight (Kg) | Total weight (Kg) | Remarks |

| 1 | Main Mixing Arm | 10434862 | Pcs | 8 | 65.00 | 520.00 | |

| 2 | Mixing Arm | 10437795 | Pcs | 4 | 61.50 | 246.00 | |

| 3 | Side Mixing Arm | 10437781 | Pcs | 2 | 65.00 | 130.00 | |

| 4 | Connection Seat | 10446973 | Pcs | 8 | 28.50 | 228.00 | |

| 5 | Short Connection Seat | 10435034 | Pcs | 6 | 28.50 | 171.00 | |

| 6 | Middle Blade | 10432721 | Pcs | 8 | 24.40 | 195.20 | |

| 7 | Scraper | 10437821 | Pcs | 4 | 24.00 | 96.00 | |

| 8 | Side Scraper | 10437771 | Pcs | 2 | 25.20 | 50.40 | |

| 9 | Guard Plate | 10437820 | Pcs | 4 | 15.20 | 60.80 | |

| 10 | Side Guard Plate | 10437772 | Pcs | 2 | 17.00 | 34.00 | |

| 11 | Upper Arc Lining Plate | 10440516 | Pcs | 24 | 12.00 | 288.00 | |

| 12 | Diamond Arc Lining Plate | 10428141 | Pcs | 32 | 12.50 | 400.00 | |

| 13 | Trapezoidal Arc Lining Plate | 10428121 | Pcs | 16 | 12.50 | 200.00 | |

| 14 | Outer Side Lining Plate | 10427426 | Pcs | 40 | 10.50 | 420.00 | |

| 15 | Inner Side Lining Plate | 10427749 | Pcs | 32 | 9.60 | 307.20 | |

| 16 | Middle End Lining Plate | 10428090 | Pcs | 4 | 18.40 | 73.60 | |

| 17 | Middle End Lining Plate ll | 10428104 | Pcs | 2 | 12.60 | 25.20 | |

| 18 | Discharge Door Cower Tile | A820401000261 | Pcs | 2 | 17.50 | 35.00 | |

| 19 | Discharge Door Edge | 10440120 | Pcs | 6 | 12.80 | 76.80 | |

| 20 | Discharge Door Arc Lining Plate | 11074193 | Pcs | 6 | 9.60 | 57.60 | |

| Total | 212 | 3614.80 |

Embark on a journey of concrete mixing excellence with our SANY JS3000 and JS3500 twin-shaft mixer blades, mixing arms, and liners. Our commitment to original replacement sets us apart, ensuring that each component is meticulously crafted to exceed industry standards. These components serve as the beating heart of your concrete mixing operation, guaranteeing seamless performance and reliability.

In the realm of aftermarket solutions, we redefine adaptability. Our components seamlessly integrate into existing setups, offering versatility and customization to meet the unique needs of your projects. This adaptability extends the lifespan of your equipment, providing a cost-effective and efficient solution for ongoing concrete production.

Durability is at the core of our design philosophy. We understand the harsh demands of the concrete mixing environment, and our components are engineered with wear-resistant materials, ensuring a robust and long-lasting performance. Whether you’re handling high-strength concrete or intricate blends, our mixer blades, mixing arms, and liners withstand the rigors of the job, contributing to consistent, high-quality results.

As a manufacturer committed to excellence, we prioritize innovation and precision in every aspect of our components. Our smooth grammar of engineering ensures that your concrete mixing process operates seamlessly, translating to increased productivity and reduced downtime.