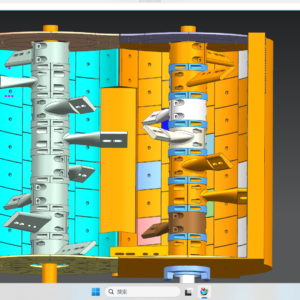

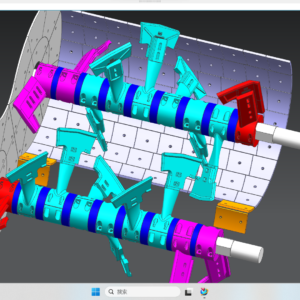

Here is a description of the BAIYINLUJi JSD4500 Mixer And Parts

| NO. | Specification | Item code | Unit. | Qty | Unit weight (Kg) | Total weight (Kg) | Remarks |

| 1 | Middle Mixing Arm | JSD4500 | Pcs | 14 | 74.2 | 1038.8 | |

| 2 | Left Mixing Arm | JSD4500 | Pcs | 4 | 69.6 | 278.4 | |

| 3 | Right Mixing Arm | JSD4500 | Pcs | 2 | 68 | 136 | |

| 4 | Mixing Arm Base | JSD4500 | Pcs | 20 | 35.2 | 704 | |

| 5 | Middle Mixing Blade | JSD4500 | Pcs | 14 | 25.8 | 361.2 | |

| 6 | Left Mixing Blade | JSD4500 | Pcs | 4 | 17.4 | 69.6 | |

| 7 | Right Mixing Blade | JSD4500 | Pcs | 2 | 17.4 | 34.8 | |

| 8 | Side Bottom Scraper | JSD4500 | Pcs | 6 | 17 | 102 | |

| 9 | Arc Lining 1 | JSD4500 | Pcs | 144 | 6.9 | 993.6 | |

| 10 | Arc Lining 2 | JSD4500 | Pcs | 36 | 6.6 | 237.6 | |

| 11 | Door Arc Lining | JSD4500 | Pcs | 4 | 4.5 | 18 | |

| 12 | End Lining 1 | JSD4500 | Pcs | 8 | 21.4 | 171.2 | |

| 13 | End Lining 2 | JSD4500 | Pcs | 4 | 20.8 | 83.2 | |

| 14 | End Lining 3 | JSD4500 | Pcs | 4 | 20.8 | 83.2 | |

| 15 | End Lining 4 | JSD4500 | Pcs | 2 | 21 | 42 | |

| 16 | End Lining 5 | JSD4500 | Pcs | 2 | 21 | 42 | |

| 17 | End Lining 6 | JSD4500 | Pcs | 2 | 18.8 | 37.6 | |

| 18 | End Lining 7 | JSD4500 | Pcs | 2 | 18.8 | 37.6 | |

| 19 | End Lining 8 | JSD4500 | Pcs | 16 | 10.9 | 174.4 | |

| Total | 262 | 4645.2 |

In the realm of concrete mixing technology, our BAIYINLUJi JSD4500 twin-shaft mixer blades, mixing arms, and liners stand out as paragons of excellence. As a distinguished manufacturer, we embody the ethos of original replacement, aftermarket innovation, and unwavering durability.

Delving into the aftermarket domain, we bring forth a commitment to innovation. Our aftermarket solutions aren’t mere substitutes; they are enhancements that elevate the performance of your mixer. Designed with a keen understanding of evolving industry needs, our aftermarket components promise efficiency, reliability, and a touch of ingenuity.

Durability is the cornerstone of our manufacturing philosophy. We understand the rigors that twin-shaft mixer components endure in demanding concrete mixing environments. As such, our blades, mixing arms, and liners are forged with materials of the highest quality, bolstering their resilience against wear and tear. This durability ensures prolonged service life, reducing downtime and enhancing the overall cost-effectiveness of your equipment.