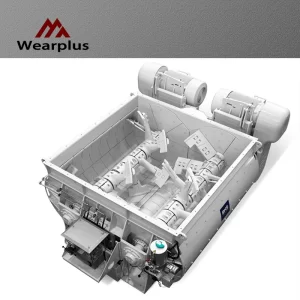

He aquí una descripción de la hormigonera CO-NELE JS4500 y sus piezas

La mezcladora de doble eje horizontal de la serie CS es una mezcladora de nueva generación desarrollada conjuntamente por la empresa CO-NELE, que fue la primera en introducir tecnología alemana avanzada en China y colaborar con empresas alemanas. Se divide en el mezclador de doble eje horizontal de alta eficiencia de la serie CHS, el mezclador de correa de doble espiral de la serie CDS y el mezclador de agua CWS. Se utiliza ampliamente en la producción de hormigón comercial, hormigón hidráulico, componentes prefabricados, materiales medioambientales, materiales para muros y otros materiales.

Características de la mezcladora de doble eje horizontal de alta eficiencia CHS:

El sello del extremo del eje está equipado con un anillo de sello de aceite flotante y un componente de sellado especialmente diseñado, formando una estructura de sello de laberinto de múltiples capas. El sello es fiable, con una gran estabilidad y una larga vida útil.

Equipada con un sistema de lubricación totalmente automático, con cuatro bombas de aceite de funcionamiento independiente que suministran aceite a alta presión. La disposición de instalación del motor montado en la parte superior incluye un dispositivo patentado de autotensado de la correa, que mejora la eficacia de la transmisión, evita el desgaste y los daños excesivos de la correa y reduce los costes de mantenimiento.

El tambor adopta un concepto de diseño de gran relación de volumen, lo que mejora eficazmente la eficacia de la mezcla, prolonga la vida útil de la junta del extremo del eje y reduce la probabilidad de que el material se adhiera al eje.

La puerta de descarga está diseñada con una gran abertura para evitar el bloqueo y las fugas de material, con bajo desgaste, sellado eficiente y efectos duraderos. El dispositivo de mezcla adopta un diseño patentado con una disposición en ángulo de 60°, lo que garantiza una mezcla uniforme, una baja resistencia y una baja probabilidad de que el material se adhiera al eje.

Equipadas con caja de engranajes planetarios de calidad militar para una transmisión suave y una gran capacidad de carga. Entre los accesorios opcionales se incluyen cajas de engranajes originales italianas, bombas de lubricación automática originales alemanas, dispositivos de limpieza de alta presión y sistemas de comprobación de temperatura y humedad.

| Modelo | CHS750 | CHS1000 | CHS1250 | CHS1500 | CHS2000 | CHS2500 | CHS3000 | CHS3500 | CHS4000 | CHS4500 | CHS5000 | CHS6000 |

| Capacidad de alimentación (L) | 1125 | 1500 | 1875 | 2250 | 3000 | 3750 | 4500 | 5250 | 6000 | 6750 | 7500 | 9000 |

| Capacidad de descarga (L) | 750 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 |

| Potencia del motor de mezcla (KW) | 30 | 37 | 22×2 | 30×2 | 37×2 | 45×2 | 55×2 | 55×2 | 75×2 | 75×2 | 90×2 | 110×2 |

| Potencia del motor de la estación de bombeo (KW) | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Brazo mezclador(Pcs) | 2*4 | 2*5 | 2*5 | 2*6 | 2*6 | 2*7 | 2*8 | 2*9 | 2*9 | 2*10 | 2*11 | 2*12 |

| NO. | Especificación | Unidad. | Cantidad | Peso unitario (Kg) | Peso total (Kg) | Observaciones |

| 1 | Cuchilla mezcladora | Pcs | 20 | 14.50 | 290.00 | |

| 2 | Cuchilla de alimentación | Pcs | 2 | 21.00 | 42.00 | |

| 3 | Hoja de retorno | Pcs | 2 | 21.00 | 42.00 | |

| 4 | Hoja final | Pcs | 4 | 13.50 | 54.00 | |

| 5 | Arco Liner I | Pcs | 112 | 10.20 | 1142.40 | 菱形 |

| 6 | Arco Liner II | Pcs | 32 | 10.50 | 336.00 | 梯形 |

| 7 | End Liner 1 | Pcs | 24 | 19.20 | 460.80 | |

| 8 | End Liner 2 | Pcs | 16 | 13.60 | 217.60 | |

| 9 | End Liner 3 | Pcs | 4 | 15.90 | 63.60 | |

| 10 | End Liner 4 | Pcs | 4 | 15.90 | 63.60 | |

| 11 | Brazo mezclador | Pcs | 20 | 66.50 | 1330.00 | |

| 12 | Brazo de alimentación | Pcs | 2 | 50.40 | 100.80 | |

| 13 | Brazo de retorno | Pcs | 2 | 50.40 | 100.80 | |

| 14 | asiento de conexión | Pcs | 24 | 24.00 | 576.00 | |

| 15 | separador | Pcs | 22 | 16.40 | 360.80 | |

| Total | 244 | 5180.40 |

Como fabricante líder de palas, brazos mezcladores y camisas para mezcladoras de doble eje CO-NELE JS4500, hacemos hincapié en la importancia de las piezas de repuesto originales, que destacan por su calidad superior y su ingeniería precisa.

Los componentes de recambio originales desempeñan un papel fundamental en el mantenimiento del rendimiento óptimo de la mezcladora. Cuando elige CO-NELE JS4500 , opta por la autenticidad y la fiabilidad. Nuestro compromiso de producir repuestos originales garantiza un ajuste perfecto, preservando la eficiencia y la longevidad de la mezcladora.

A diferencia de las alternativas del mercado posventa, nuestros recambios originales garantizan la compatibilidad, reduciendo el riesgo de averías y tiempos de inactividad. Damos prioridad a las especificaciones exactas y a los materiales de alta calidad para ofrecer componentes que reflejen el rendimiento de las piezas originales.