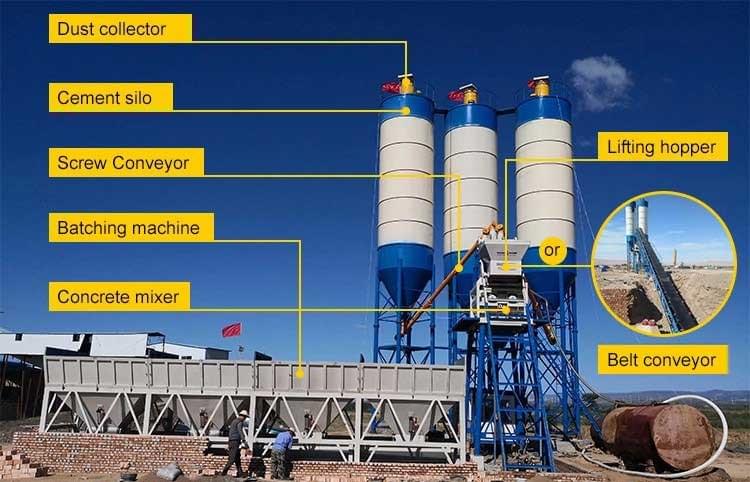

Concrete mixing plant usually consist of multiple parts, each of which has its specific functions and roles. The following is a detailed description of each part of the concrete batching plant:

1.Skeleton Structure:

The skeleton structure of a concrete batching plant, usually constructed of steel or concrete, provides support and stability to the entire facility. The design of the skeleton structure needs to take into account the weight and workload of the equipment to ensure that it can withstand pressure and vibration under various conditions.

2.Storage silo:

储料仓是用来储存原材料的地方,包括水泥、沙子、骨料和添加剂。这些原材料在搅拌过程中将按一定比例混合在一起形成混凝土。储料仓通常设计为封闭结构,以保护原材料免受外部环境的影响。

3.Conveying system:

Conveying systems are used to transport raw materials from storage silos to the mixer for blending. This includes a variety of conveying equipment such as belt conveyors, screw conveyors, bucket elevators etc. The design of the conveying system needs to take into account the type and particle size of the raw material to ensure that it can be conveyed efficiently to the mixer.

4.mixer:

Mixer is the core equipment of concrete mixing plant, which is used to mix various raw materials together to form concrete. The mixer is usually designed with horizontal or vertical shafts, with mixing blades installed inside to mix the raw materials thoroughly through rotation. The design of the mixer needs to consider the mixing efficiency and the quality requirements of the concrete.

5.Control system:reload-alert

The control system is used to monitor and control the operation of the concrete mixing plant. This includes various sensors and automation equipment to monitor the flow of raw materials and parameters of the mixing process, and adjust the operating status of the equipment as needed. The control system can also record and store data from the production process for subsequent analysis and optimization.

6.Auxiliary equipment:reload-alert

In addition to the above main components, the concrete mixing plant may also be equipped with some auxiliary equipment, such as water pumps, air compressors and dust removal equipment. These devices are often used to assist in the transportation and handling of raw materials, as well as to keep the production environment clean and safe.

The above is a detailed description of the main parts of the concrete mixing plant. Each part plays an important role in the entire production process, jointly ensuring the production efficiency and quality of concrete.