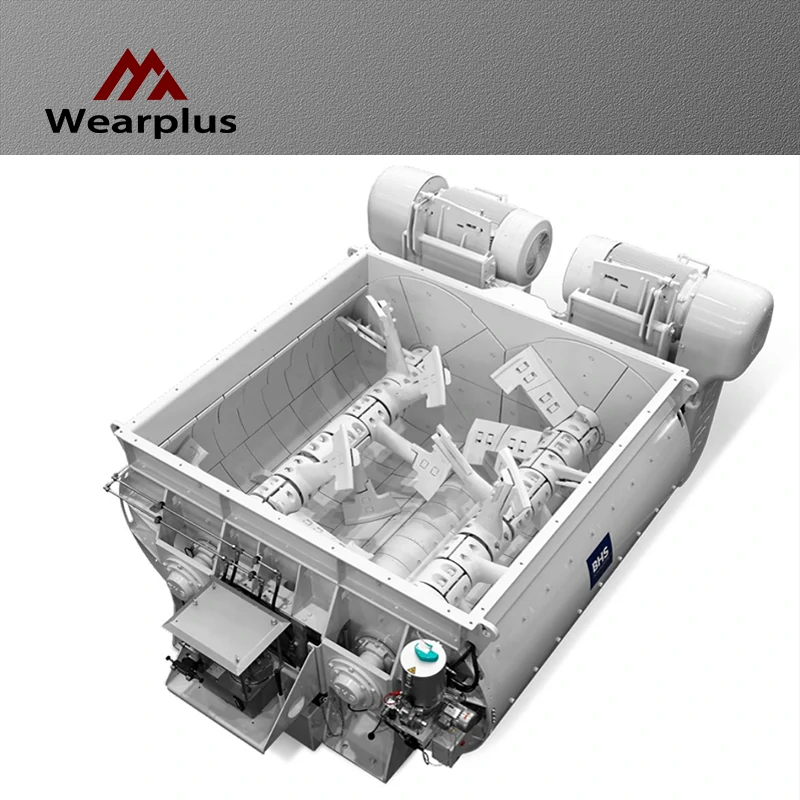

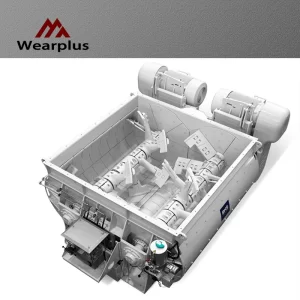

Voici une description du BHS DKX4.0 Mixer And Parts

Avantages du produit

Homogénéité élevée et constante du mélange et cycles de mélange courts

● Augmentation rapide de l'homogénéité du mélange grâce à un échange intensif de matières.

● Cohérence et homogénéité uniformes à chaque cycle de mélange.

Efficacité énergétique optimale

● Excellente performance de mélange malgré une faible vitesse de rotation du mélangeur.

● Préservation de la structure granulaire des différents composants de la formulation.

● Faible consommation d'énergie spécifique grâce à des temps de mélange courts, un mécanisme de mélange optimisé et un entraînement efficace.

La conception se traduit par une faible usure

● Faible usure des outils de mélange et du revêtement de l'auge de mélange en raison des faibles vitesses et de la conception compacte.

● Une usure nettement moins importante qu'avec les mélangeurs à plateaux ou planétaires.

● Conception optimisée de toutes les pièces soumises à l'usure.

Production efficace de béton

● Excellente libération des liants en peu de temps.

● Crée un potentiel de réduction de la quantité de liant nécessaire.

● Distribution uniforme et rapide des additifs et des adjuvants dans tout le volume du mélange.

● Possibilité de réaliser de petits lots à partir de 10% du niveau de remplissage nominal.

● Un investissement sûr compte tenu des formulations modernes du béton.

● Prend en charge les cycles de mélange hybrides (lent - rapide - lent).

| Type | Charge sèche

agrégats et liant |

Compacté

béton |

Production de béton compacté | Système d'entraînement

(prêt à l'emploi) |

Taille maximale des agrégats | ||||

| avec camion malaxeur

décharge 1) |

avec camion ouvert

décharge 2) |

Prêt à l'emploi

béton |

Hydrodam

concret 4) |

||||||

| DKX 1.00 | 2 yd³ 1.5 m³ |

1,3 yd³1m³ | 58 cycles/h | 76 yd³/h 58 m³/h |

60 cycles/h | 78 yd³/h 60 m³/h |

50 ch 37 kW |

212in 64 mm | 3 dans 80 mm |

| DKX 1.25 | 2.5 yd³ 1.88 m³ |

1.6 yd³ 1.25 m³ |

53 cycles/h | 86 yd³/h 66 m³/h |

53 cycles/h | 86 yd³/h 66 m³/h |

60 ch 45 kW |

212in 64 mm | 5 en 125 mm |

| DKX 2.25 | 4.5 yd³ 3.38 m³ |

3 yd³ 2.25 m³ |

46 cycles/h | 136 yd³/h 104 m³/h |

50 cycles/h | 148 yd³/h 113 m³/h |

100 ch 75 kW |

21zin 64 mm | 6 en 150 mm |

| DKX 3.00 | 6 yd³ 4.5 m³ |

4 yd³ 3 m³ |

44 cycles/h | 173 yd³/h 132 m³/h |

53 cycles/h | 208 yd³/h 159 m³/h |

2×75 hp 2×55 kW |

2tzin 64 mm | 6 en 150 mm |

| DKX 4.00 | 7.9 yd³6m³ | 5.2 yd³4 m³ | 39 cycles/h | 204 yd³/h 156 m³/h |

49 cycles/h | 256 yd³/h 196 m³/h |

2×100 hp 2×75 kW |

21zin 64 mm | 614in 160 mm |

| DKX 4.50 | 9 yd³ 6.75 m³ |

6 yd³ 4.5 m³ |

37 cycles/h | 218 yd³/h 167 m³/h |

51 cycles/h | 301 yd³/h 230 m³/h |

2×100 hp 2×75 kW |

212in 64 mm | 6 en 160 mm |

| DKX 4.0 | ||||||

| NON. | Nom | quantité | unité | à pondération unique | Poids total (kg) | Remarques |

| 1 | Bras central | 12 | a | 62 | 744 | |

| 2 | Bras gauche | 4 | a | 58 | 232 | |

| 3 | Bras droit | 2 | a | 60 | 120 | |

| 4 | Siège central | 12 | a | 21 | 252 | |

| 5 | Siège latéral | 6 | a | 20 | 120 | |

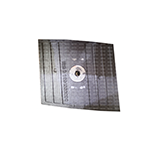

| 6 | Doublure de l'arc supérieur | 16 | a | 27 | 432 | |

| 7 | Arc de cercle rhombique | 48 | a | 12 | 576 | |

| 8 | Doublure d'arc trapézoïdal | 16 | a | 12 | 192 | |

| 9 | Doublure d'extrémité① | 8 | a | 36.5 | 292 | |

| 10 | Doublure d'extrémité② | 8 | a | 36 | 288 | |

| 11 | Doublure d'extrémité③ | 8 | a | 32 | 256 | |

| 12 | Tête de tuile | 4 | a | 21 | 84 | |

| 13 | Protections de portes | 8 | a | 8.3 | 66.4 | |

| 14 | Bord de la porte | 6 | a | 9.6 | 57.6 | |

| 15 | Lobe moyen | 12 | a | 25 | 300 | |

| 16 | Lobe gauche | 4 | a | 17 | 68 | |

| 17 | Lobe droit | 2 | a | 19 | 38 | |

| 18 | Grattoir gauche | 4 | a | 14 | 56 | |

| 19 | Grattoir droit | 2 | a | 14.5 | 29 | |

| 20 | Total | 182 | 4203 | |||

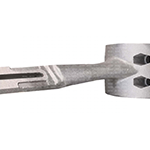

BHS Twin Shaft Batch Mixer Genuine Matching Quality Spare parts(DKX0.50 0.75 1.00 1.25 1.67 2.00 2.25 2.50 2.75 3.00 3.33 3.50 4.00 4.50 5.00 6.00) :Groupe d'étanchéité (ensembles) de la tête de l'arbre de mélange et de l'extrémité de la boîte de vitesses, pièces en alliage résistant à l'usure : pales de mélange, racleur, plaque de revêtement, arbre de mélange, bras de mélange, accouplement d'amortissement en caoutchouc, etc.

OEM(Original)

Groupe d'étanchéité de l'arbre de mélange (côté boîte de vitesses/ côté palier)

Arbre principal du mélangeur

Lame droite du mélangeur

Plaque droite du mélangeur

Rebord de la porte du mélangeur

Couvercle de la porte du mélangeur

Lame gauche du mélangeur

Plaque gauche du mélangeur

Lame centrale du mélangeur

Bras central du mélangeur c/w couple

Bras droit du mélangeur c/w couple

Bras gauche du mélangeur c/w couple

Pièces supérieures du mélangeur

Par le biais d'une tuile interne

Par le biais d'une tuile externe

Vis de la pale de mélange

Revêtement en fonte dure de la paroi avant

Shim

Protection des bras ( G/R )

Boulon/écrou/disque hexagonal~M24*110

Vis à tête fraisée

Entretoise de bras

Protection des rouleaux

Élément en caoutchouc

Solutions pour les pièces de rechange systématiques telles que le groupe d'étanchéité, l'arbre de mélange et le boîtier de roulement du mélangeur à deux arbres BHS DKX3.0/DKX2.0.

Catalogue de pièces détachées :

100543000 ARBRE DE MÉLANGE

100989500 BUSH D'ARBRE

100709700 ANNEAU DE RETENUE

100260400 DUST COVER

100991700 MANCHON DE DISTANCE

100003800 COUVERTURE DE ROULEMENT

100003900 BOÎTE DE ROULEMENT

504306600 ANNEAU DE RÉGLAGE DU LAMINUM

504302000 JOINT À FACE AXIALE

507079100 BAGUE D'ÉTANCHÉITÉ DE L'ARBRE

101059500 BAGUE D'ÉTANCHÉITÉ

506768000 ROULEAU À ALIGNEMENT AUTOMATIQUE BRG

100260300 ANNEAU DE PORT

100004000 BUSH D'ARBRE

100004300 END DISK

100004600 COUVERTURE DE ROULEMENT

100004400 BOÎTE DE ROULEMENT

100991500 MANCHON DE DISTANCE

507085000 BAGUE D'ÉTANCHÉITÉ DE L'ARBRE

506770000 ROULEAU À ALIGNEMENT AUTOMATIQUE BRG

504306200 ANNEAU DE RÉGLAGE DU LAMINUM

500136300 BOULON HEXAGONE

503361600 BAGUE DE PRINTEMPS

500136500 BOULON HEXAGONE

500133600 BOULON HEXAGONE

503361200 BAGUE DE PRINTEMPS

503041200 ÉCROU HEXAGONE

500505600 VIS DE CULASSE

500506300 VIS DE CULASSE

503041000 ÉCROU HEXAGONE

503361000 BAGUE DE PRINTEMPS

500223000 BOULON HEXAGONAL À POINTE PLEINE

500142600 BOULON HEXAGONE

503346400 RONDELLE DE BLOCAGE

100965100 CLÉ EN PLUMES

506008800 CLÉ EN PLUMES

500553600 VIS DE CULASSE

Découvrez une qualité inégalée avec nos lames, bras de mélange et revêtements de malaxeur à double arbre pour béton BHS DKX4.0. En tant que pièces de rechange d'origine, elles sont synonymes de durabilité et garantissent des performances à long terme. Choisissez nos solutions de rechange pour une compatibilité parfaite et une efficacité et une productivité optimales.

Notre engagement envers l'excellence est évident dans la sélection méticuleuse des matériaux, avec des caractéristiques de résistance à l'usure qui garantissent une durée de vie prolongée. La série BHS DKX4.0 est conçue pour durer, ce qui en fait le choix privilégié pour diverses applications de mélange de béton.

En tant que fabricant réputé, nous donnons la priorité à l'ingénierie de précision, en veillant à ce que chaque composant s'intègre parfaitement à votre mélangeur. La nature de remplacement d'origine de nos produits signifie que vous pouvez faire confiance à leur compatibilité et à leur performance, imitant ou même dépassant les normes établies par l'équipement d'origine.

Dans le paysage concurrentiel des équipements de malaxage du béton, nos solutions après-vente se distinguent par leur fiabilité et leur rentabilité. Nous comprenons l'importance de minimiser les temps d'arrêt et de maximiser l'efficacité de vos opérations. C'est pourquoi nos pales de malaxeur BHS DKX4.0, nos bras de malaxage et nos revêtements sont conçus pour répondre aux exigences rigoureuses de l'industrie du béton.

Lorsque vous choisissez nos produits, vous n'achetez pas seulement des pièces de rechange, vous investissez dans la longévité et l'efficacité de votre équipement de malaxage du béton. Notre engagement en faveur de la qualité, de la durabilité et de l'assistance après-vente vous garantit une transition en douceur entre les composants usés et les performances améliorées.

Faites le bon choix pour vos besoins en mélange de béton : choisissez les pales, les bras de mélange et les revêtements de malaxeur BHS DKX4.0 pour une durabilité et une fiabilité inégalées. Faites équipe avec nous pour des solutions de remplacement d'origine qui redéfinissent les normes d'excellence dans l'industrie du béton.