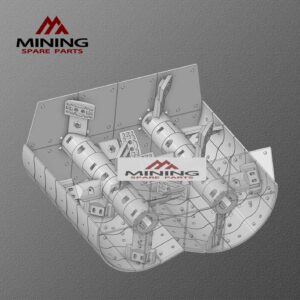

Here is a description of the NFLG 4500E Mixer And Parts

| NO. | Specification | Item code | Qty | Unit weight (Kg) | Total weight (Kg) | Remarks |

| 1 | Feed long arm (positive) | 5.2-2 | 12 | 59.8 | 717.6 | |

| 2 | Feed long arm (reverse) | 5.4-3 | 4 | 59.8 | 239.2 | |

| 3 | Side feed arm (positive) | 5.7-3 | 2 | 62 | 124 | XC4500 |

| 4 | Side feed arm (reverse) | 5.8-3 | 2 | 62 | .124 | XC4500 |

| 5 | Lower seat | XC5.1-4 | 28 | 29.4 | 823.2 | |

| 6 | Long feed blade A | 5.3-1 | 10 | 12.3 | 123 | |

| 7 | Long return blade A | 5.4-1 | 2 | 12.3 | 24.6 | |

| 8 | Side feed blade long | 5.2-1 | 2 | 22.8 | 45.6 | |

| 9 | Side return blade long | 5.5-1 | 2 | 22.8 | 45.6 | |

| 10 | Long feed blade B | 5.3-2 | 10 | 12.3 | 123 | |

| 11 | Long return blade B | 5.4-2 | 2 | 12.3 | 24.6 | |

| 12 | Side feed blade A | 5.7-1A | 2 | 25.2 | 50.4 | JS4500XC5.3-1/24.2kg |

| 13 | Side return blade A | 5.8-1A | 2 | 25.6 | 51.2 | JS4500XC5.1-1/24.2kg |

| 14 | Side feed blade B | 5.7-2A | 2 | 13.6 | 27.2 | JS4500XC5.3-2/18.6kg |

| 15 | Side return blade B | 5.8-2A | 2 | 13.4 | 26.8 | JS4500XC5.1-2/18.6kg |

| 16 | Diamond-shaped arc liner | XC3-1 | 144 | 6.92 | 996.48 | |

| 17 | Trapezoidal arc liner | XC3-2 | 36 | 6.56 | 236.16 | |

| 18 | Upper mouth liner | 0 | ||||

| 19 | Arc-shaped edge right A | JS4500C2.3-3 | 2 | 23 | 46 | 门沿JSL2250XC3-2/18件5.8kg |

| 20 | Arc-shaped edge right B | JS4500C2.3-4 | 2 | 23 | 46 | |

| 21 | Discharge door connecting flange sealing plate A | JSL2250XC2.3-5 | 2 | 11.2 | 22.4 | 瓦头JSL4522C3-3/4件18.6kg |

| 22 | Discharge door connecting flange sealing plate B | JSL2250XC2.3-6 | 14 | 8 | 112 | |

| 23 | Side liner 1 | XC3-3 | 8 | 21.4 | 171.2 | |

| 24 | Side liner 2 | XC3-4 | 4 | 20.4 | 81.6 | |

| 25 | Side liner 3 | XC3-5 | 4 | 20.4 | 81.6 | |

| 26 | Side liner 4 | XC3-6 | 4 | 18.8 | 75.2 | |

| 27 | Side liner 5 | XC3-7 | 4 | 18.8 | 75.2 | |

| 28 | Side liner 6 | XC3-8 | 16 | 10.4 | 166.4 | |

| 324 | 4680.24 |

Elevate your concrete mixing experience with SNFLG 4500E twin-shaft mixer components. Our offerings stand out as original replacements, ensuring a seamless fit and top-notch performance. In the realm of aftermarket solutions, we provide unparalleled options, catering to diverse needs. The durability of our blades, mixing arms, and liners is a testament to our commitment to quality.

Original replacement components are vital for maintaining the efficiency of your twin-shaft mixer. At our manufacturing facility, we craft precision-engineered blades, mixing arms, and liners designed to seamlessly replace the original parts. This guarantees a perfect fit, restoring your mixer to its optimal functionality.

In the aftermarket segment, we go beyond conventional alternatives. Our innovative solutions are crafted to enhance the performance of your mixer, meeting and exceeding industry standards. We understand the importance of flexibility in choosing components, and our aftermarket options provide a diverse range to suit your specific requirements.

Durability is at the core of our products. Our blades, mixing arms, and liners are built to withstand the rigors of heavy-duty concrete mixing. Whether it’s the original replacement or an aftermarket solution, our components boast exceptional wear resistance, ensuring a prolonged lifespan for your mixer.